Story and photos by Mark Wing

The primary focus of this work day at Larry’s garage was to make roadworthy Don Neidigk’s 1926 coupe. Other projects included the Duncan’s rear differential on their 1920 touring car, and continuing on Dave Ferro’s speedster engine. Smaller projects included Kirk Peterson adjusting a newly installed NH carburetor and Mark Wing cleaning a pair of 1923-25 hood shelves.

Don Neidigk acquired a 1926 coupe in October 2018 almost by accident. He had inquired about a coupe for sale in San Diego, but due to the seller’s advanced age and hearing problems, he thought that Don had agreed to buy the car when in fact he was only seeking information. Don only discovered the misunderstanding when the elderly seller was in the process of delivering it to Don in New Mexico! Even with this communication problem, Don decided to move forward with the purchase and has been trying to correct a series of problems and make the car roadworthy since then. One of the first items was to recore the radiator. Using the parts from three donor radiators, JB Radiator in Albuquerque assembled a radiator for Don with a new core. This approach was about half the cost of a new radiator.

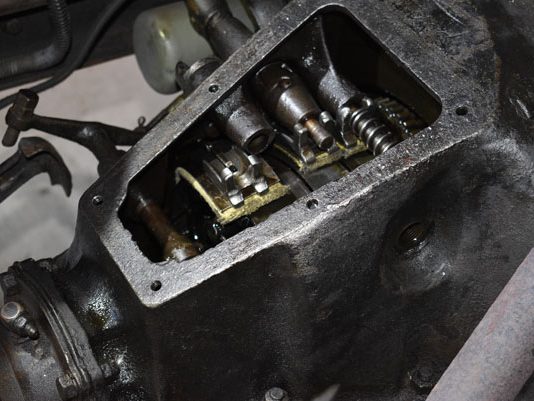

On this work day at Larry’s garage, the transmission bands on Don’s coupe needed replacement and electrical/ignition problems addressed. This was the first time the coupe had made an appearance at Larry’s garage as Don didn’t have a trailer to transport it. Senior club member Mark Dominguez offered to bring the coupe on his flatbed trailer to the work day so Don was finally able to access Larry Azevedo’s expertise as well as the knowledge and manpower of the other club members. After the band replacement, correcting some wiring issues, and other adjustments, the car ran much better. We heard that on the drive home, the coupe was overheating, the floorboards had caught on fire, and a lot of coolant was spraying on the windshield. Evidently, even with the new radiator core, some scale and rust has loosened in the block and has cut off coolant circulation. So Don has more work to do, but a lot of progress was made and these remaining issues should be sorted out soon. Good luck Don!

Paul and Marilyn Duncan had largely restored the 1920 Model T touring car pulled out of Marilyn’s family barn almost 10 years ago. The only part of the car that hadn’t gotten any attention was the rear differential. It was suspected that the last time the rear differential had any parts replaced was in the 1930’s. Now that Larry had the time available, and the differential was starting to make noise, it was time to take it apart and rebuild it. The Duncan’s made the decision to restore the stock differential as opposed to adding a Ruckstell axle.

Dave Ferro has been working on a 1927 engine for a speedster project for some time. This engine has a SCAT crankshaft, Stipe 260 camshaft, and will have a Bosch distributor. On this day, Dave was dry fitting the 4-dip engine pan and hogshead to confirm the straightness of the pan. Unfortunately, the pan was a bit bent (which would put a strain on the 4th main bearing. Larry nor the club have a K.R. Wilson pan straightening table. Long ago, Larry’s late father (George) had developed a method of pulling the pan in the desired direction using a come-along. Larry refined his father’s “Rube Goldberg” design by adding a angle iron extension to increase leverage. Some careful measurements and observations determined the direction of the force. After a couple of tries, the 4th main bearing cap appears to be in much better concentric alignment as well as the 4th main bearing mounting holes!

It was a very busy work day and a lot was accomplished. Thanks Larry!