On this unseasonably warm Saturday, Larry and Lorna were hosting out-of-town visitors – fellow MTFCA members Duane and Nita Nicholson from Rochester, Wisconsin. The Nicholson’s are members of the Dairyland Tin Lizzies and own a 1922 Coupe,1926 Fordor, and three other non-running Model T’s. Larry and Lorna had recently toured with the Nicholson’s in Nebraska. The Nicholson’s had escaped Wisconsin’s 0 degree days and were enjoying Albuquerque’s spring-like 70 degrees!

Joining us for the first time was Stan Gauna’s granddaughter’s boyfriend Cody Krug. Cody is our latest, and among the youngest, Tin Lizzies of Albuquerque member. Welcome Cody! Joining us also was Mike Garcia, who owns a 1926 Model TT dump truck. We hope to see more of Mike and his dump truck in the future.

Larry’s work party started with Vernon Armstrong bringing the engine/transmission from Bruce Daniel’s 1925 Tudor in his pickup truck. Some months ago, Bruce heard a loud explosion while driving the Tudor and he knew the poor car had suffered a catastrophic mechanical failure. A 6-inch hole had been blown through the hogs head, probably from a thrown magnet! Luckily, Bruce wasn’t injured and now it was time to disassemble the engine and transmission and begin repairs. Helping Bruce with his disassembly project were Vernon, Russell, Stan, and Cody.

Tom Miles was cleaning parts to his 1926 touring car vaporizer carburetor. The engine has already been rebuilt and runs very smoothly.

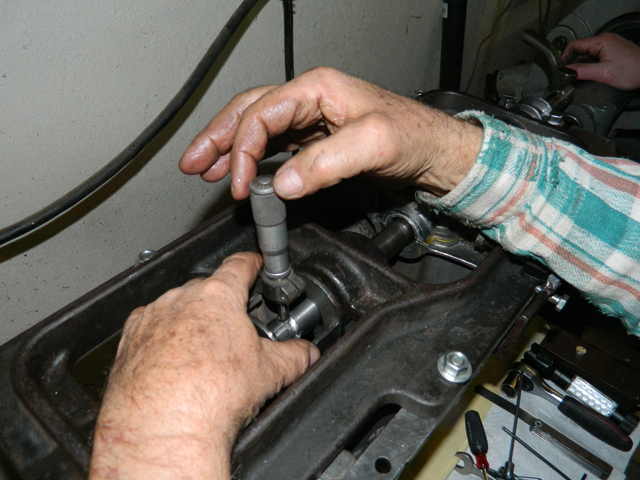

Larry, Mark, and Duane were babbitting the main bearings and caps on Mark’s 1925 touring car engine. This is the sixteen engine that Larry has babbitted and he has perfected his technique to the point of getting excellent quality and predicable results. In fact, Larry conducted a babbitting demonstration with Jahn Wright at the 2012 MTFCA Business Meeting hosted by the Tin Lizzies of Albuquerque. Once the babbitting was done, the block was mounted to the lathe and the bearings were lined bored. This rebuild will use a balanced stock diameter SCAT crankshaft. Larry was boring the main bearings for 0.0015″ clearance with shims installed. The next step, currently in progress is preparation of the rods and caps. The rods have been cleaned and matched with selected caps to achieve a total weight within two grams prior to the babbitting process.

Thank you for a fantastic and productive work party!