Larry’s garage was humming with activity after our club breakfast at the Cracker Barrel restaurant on Saturday, April 9th. Joining us for the first time this morning was James, a friend of Ken Carpenter. James owns a 1948 Chevy truck, so he’s no stranger to older vehicles. Ken brought his family’s 1923 touring car (converted to a pickup truck) for adjustments to the transmission bands. At a previous work party, a shorted starter switch was fixed and the carburetor was cleaned. Once he truck could start reliably, the bands were adjusted and Ken and James were able to take it out for spin around Corrales.

Skip Dunn trailered his 1914 Model T touring car from Los Alamos, NM to Larry’s to install new tires on his wheels. Skip had salvaged the new Universal tires from the prop car used by the Santa Fe Opera. Dave M. and Kirby O. assisted Skip on the tire installation.

The Lance family was hard at work on the family’s 1919 engine restoration project. Phil was rebuilding his generator with a kit donated by Bill Hansen. The comprehensive kit included new bearings, field coils, insulators, and brushes. It will be as good as new once assembled. Phil’s daughters Danielle and Jessalyn received a lesson in line boring from Larry. These young ladies were shown how to operate Larry’s large lathe and measured their machining progress with depth micrometers. This may be a first in the annals of the Model T hobby! We can look forward to an account of the Lance family engine rebuilding adventures in a published article in the future. Way to go Danielle and Jessalyn!

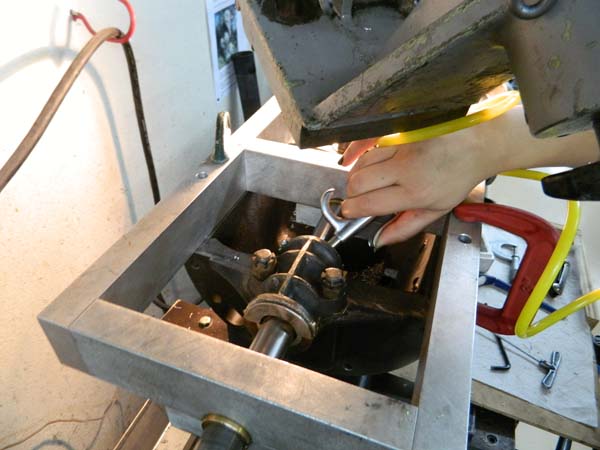

Mark continued assembling his 1925 touring car engine/transmission. Larry had installed new Oilite bushings and modern oil seals on the hogs head. A generator was tested and it’s ready for installation as is a newly rebuilt starter. The exhaust manifold had warped approximately 1/8″ and Larry had created a fixture to bend manifolds back into shape. This clever fixture has centering holes corresponding to each of the exhaust port holes. The two holes nearest the threaded part of the manifold can be moved via fine-threaded bolts once the manifold is heated red hot. The majority of the heat is applied to the top of the manifold (where the metal is compressed). This procedure worked great for Mark’s manifold, and Larry performed the same technique on Phil Lance’s manifold as well. Phil’s needed to be bent approximately 3/8″ but the operation was successful with no cracking. The exhaust port gland rings now available will prevent this metal sagging problem in the future.

Michael and Betty Housholder made great progress on rebuilding Betty’s 1921 Model T coupe engine/transmission. As documented from the previous work party, the transmission magnets let loose and a piece of one of them lodged in the top of the hogs head. With Bob Ross’ help, the approximately 1-inch hole was brazed. With Don Mitchell’s and Larry’s help, the pan was cleaned. Surprisingly, Betty’s transmission and engine were in good condition, considering the catastrophic failure of the transmission. Michael was going to convert the car to a distributor system anyway, so the magnets were removed in favor of oil slingers. Michael was also checking the main rod bearings for wear, but found that the 10-year old rebuilt engine was still in good tight shape, so no new babbitting is required.

Thank you Larry for another fun and productive work party!