Story and photos by Mark Wing (unless otherwise noted)

There were four projects in progress at Larry’s Garage on Saturday, January 18th. Frank Lewark continued working on his 1924 speedster engine/transmission, Kirk Peterson was working on the Montana 500 engine for his 1925 coupe, Paul and Marilyn Duncan had their 1920 touring car in the shop to correct an ignition problem, and Mark Wing was working on a set of hinges for his 1915 Coupelet restoration project.

Frank Lewark (Lemitar, NM) continued working on his engine/transmission for his 1924 speedster project. Frank had a nicely rebuilt field coil and it was time to mount it. He and Larry found that the cast iron standoffs on the field coil were too long by approx. 0013″ so the field coil was machined to a more workable height on Larry’s Bridgeport mill. Frank also used a fixture to center the middle camshaft bearing for reaming.

Kirk Peterson and Mark Dominguez were busy assembling the valves, springs, and keepers on Kirk’s Montana 500 engine for “Buster”, Kirk’s “barn fresh” 1925 coupe. He had an engine that had been restored to stock, but the Montana 500 build meant replacing the stock camshaft with a Stipe 280 unit. This change required that new valves be cut to length which Larry carried out on his valve grinding and cutoff station.

Larry noticed that Paul and Marilyn Duncan’s 1920 Model T touring car was running rough when they pulled up to his garage in the morning so Larry inspected the electrical system for problems. By shorting out each of the spark plugs, he detected a weak spark on the number two cylinder. He determined that the Anderson Timer in the Duncan’s touring wasn’t performing well and suggested changing the commutator to a New Day Timer from the Club’s stock. After the New Day Timer was installed, the touring did run much better!

In December, Mark Wing purchased the remnants of a 1915 Coupelet body that belonged to Larry’s father George. The Coupelet had been caught in a fire when in was stored at a friends house in Northern California in the late 1980’s and the body was destroyed. George sifted through the ashes and recovered as many of the body parts as he could with the intention of restoring the car someday. Later in time, George did restore the original chassis, with it’s original February 1915 build date engine. He also managed to track down another Coupelet body that was mounted to a later chassis. This 1916-style Coupelet body was mated to the 1915 chassis and this car is now in Larry Azevedo’s collection in Corrales, NM. Larry generously sold what remained of the original 1915 body parts from his father’s estate, which included many of the cast iron parts and some body panels, to fellow Tin Lizzies member Mark Wing. “It’s an honor to be entrusted by Larry with these rare parts with their rich family history. Every effort will be made to do as accurate and as high-quality a restoration as possible”.

On December 19th, Mark and Susan Wing visited with Russ Furstnow in Flagstaff, AZ to see his recently restored 1915 Coupelet. Russ, who is a recognized expert in the Model T hobby and a former Chief Judge for the Model T Ford Club International, was very gracious with his time and expertise. His 1915 Coupelet was finished in 2019 and has been outstandingly researched and restored. Russ was a wealth of information and was a source some of the Wing project’s missing parts! Russ had his Coupelet body restored by Ray Wells “The Craftsman” of El Cajon, CA who is considered a master at restoring and recreating Model T wood bodies.

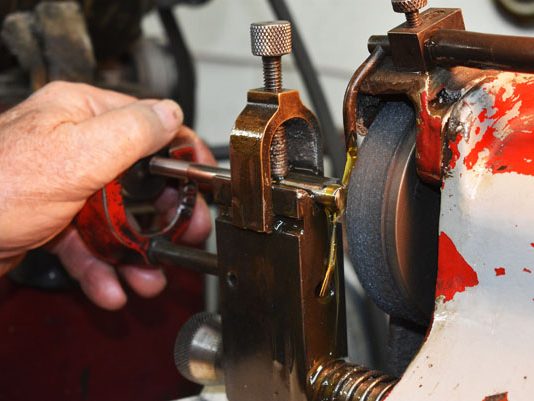

The next day (Dec. 20th), Mark and Susan visited Ray Wells’ workshop (east of San Diego) to discuss the 1915 Coupelet restoration project. In the past 30 plus years, Ray has created over 1,000 antique car bodies, the bulk of which are Model T’s. He’s created/restored approximately 10 Coupelet bodies and was working on two of them (a 1915 and a 1916) at the time of the visit. Without the original wood to use as patterns it was logical to have Ray recreate the Wing project 1915 body using as many original parts as possible. The set of hinges being worked on at Larry’s Garage on this (Jan. 18th) work day are destined for this body. Starting with multiple loose hinges from several sources, the parts have been mixed and matched to create two sets of three hinges per side of the correct dimensions and hole patterns. Larry used one of his lathes to turn down carriage bolt heads to the correct diameter and to remove the square part of the bolt to create the hinge pins. Once finished and primed, these hinges will join other batches of parts to be shipped to Ray Wells. Ray recently reported that the body is making good progress and (at the time of this article), he’s waiting for the two rear quarter panels which will require some dent removal and leading before shipping them to him in El Cajon, CA.

It was another enjoyable, interesting, and productive day at Larry’s Garage! Thank you Larry.