This Saturday was Larry’s first work party of the new year. The morning temperature was pretty chilly at around 20 degrees which probably accounted for no Model Ts being driven to the work party.

Joining us for the first time was Jeffrey Samson and his children – Jachai (9) and Naomi (4). Jeffrey is an Civil Engineer with a awareness that it would be fun and educational for him and his kids to learn more about how these early machines work and about machining. Larry gave them a tour of his shop and his diverse collection of Model Ts. Jachai and Naomi were each given a pair of pliers to introduce them to hand tools and to give them a project to work on. Their task, under their father’s watchful eye, was to clean the pliers and personalize them by engraving their names on the handles. Larry provided a can of blueing, which when brushed on the plier handles and allowed to dry, made it easier to write their names and follow the markings with the engraving tool.

Later that morning, the Greenwood family – Aaron, Whitney, Liam (4), and Eddie (18 months) attended their second work party. Liam engraved his name on his plier that he had cleaned up at the last work party. We hope these visits to Larry’s garage and their activities there spark and interest in the hobby.

Other projects on this day included John Hayne bringing a carburetor for disassembly and cleaning. He also got Larry’s assistance straightening a frightfully bent and torn early firewall bracket. Larry fixed the pretzel-like firewall bracket by heating it via oxy acetylene and welding the tear. John will do the final finishing at home.

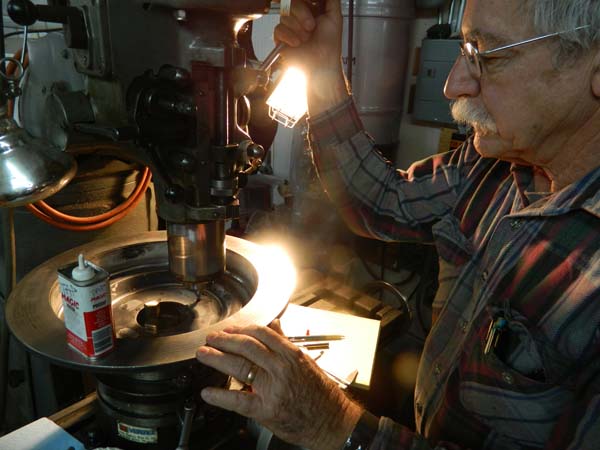

Mark Wing brought large drum rear differential/Ruckstell housings to replace their worn out brake cam and spring shackle bushings. Large drum disk brakes were also drilled out to accept a wood wheel 6-hole pattern. These disk brakes were an Ebay purchase originally intended for wire wheels with the 5 bolt hole pattern. They were acquired before the smaller diameter disk brakes were available. The original 5 holes were plugged, welded, and ground down. Using his Bridgeport mill, Larry machined the set of disk brakes to perfectly match the Dan McEachern floating hubs that were going to mate with them. At the next work party, the brakes and floating hubs will be painted and assembled with the round headed original style bolts.

Thank you Larry for a great work party with our very new and young Tin Lizzie enthusiasts!