This was the first work party after the 2014 MTFCA Business Meeting and cruise aboard a Royal Caribbean liner. With Larry and other members back from the fabulous trip, it was time to get back to Model T projects.

Neil O’Brien brought TT spokes and his powder coated felloes for assembly. A previous attempt had only brought moderate success due to incorrectly machined spokes. It was time to try it again.

Tom Miles was cleaning up spring shackles and lining brake shoes for his 1926 touring car project. Helping him were Michael and Russell.

Bruce Daniel was reaming the triple gear bearings for his 1925 Tudor that had thrown a magnet through his hog head – creating quite a mess in the transmission!

John Hayne brought a universal joint for his speedster project. He wasn’t able to remove the bent pin holding the assembly together and had come to the work party to give it a try. With Michael’s help, and a solid backing surface, the pin was pounded out.

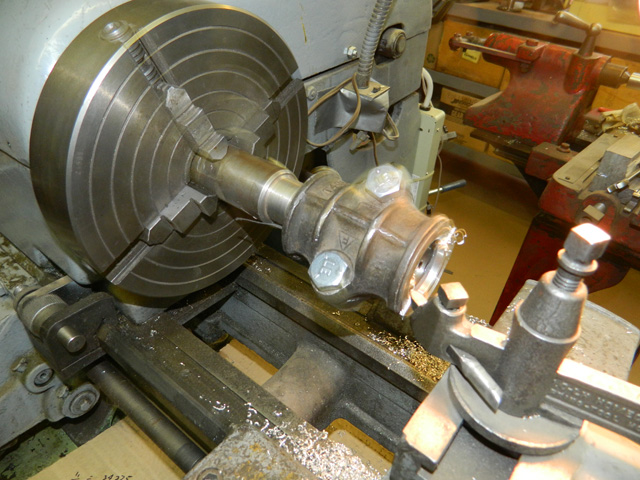

Mark Wing’s 1925 engine was ready to have its new SCAT balanced crankshaft fitted to the block. At a previous work party, Larry had babbitted the main bearings and line-bored to stock size. Now, the bearings had to be chamfered and the rear bearing cap machined to the correct length to allow for the perfect amount of end play. Larry showed Roger and Mark how to do the lathe operation to face off the bearing cap. After some measurements and calculation, the cap mated perfectly to the block with only around 0.002″ end play! The other caps were adjusted to 0.015″ clearance using Plastigage. Larry was very happy with the way it turned out and it is a thing of beauty. It is snug, but rotates easily and hints at the super smooth operation expected once the engine is on the test stand.

For this project, the rods and caps that came out of the touring were mixed and matched (as needed) with ones out of Larry’s stock to find combinations that weighed in within 2 grams. This attention to detail and checking the flywheel for balance will also contribute to a super smooth and balanced engine. Babbitting the rods and rod caps is the next step in the process.

Thank you to Larry for another educational and productive Tin Lizzie work party!